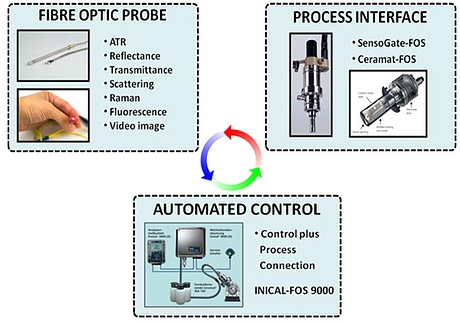

Process Control

Chemical production facilities often require process optimization. Despite being widely recognised as an important part of the production process, it typically remains an offline or at line task. The uncertainties and disturbances that happen during production processes are inherent in real applications, therefore deeper process understanding through online real-time analytical measurements.

Optical analysis methods require an observation window for in-situ applications. The window needs to remain clean to allow reliable analysis of the chemical and biological processes. Optical methods can be utilized only if the following requirements are met:

- Cleaning of the observation window

- The check of the window cleanness

- Active control of the analyser

- Zero baselines at any time

- The ability to clean all parts that have come in contact with the product (surfaces, seals, etc.) in accordance with the guidelines of GMP, Hygiene etc.

Applications:

- Refinery production

- Fuels

- Bio-fuels

- Solvents

- Speciality Chemicals

- Food Products

- Pharmaceutical Products and their Development