Polycrystalline IR-Fibers

Core / Clad Polycrystalline Infra-Red (PIR-) fibers are a unique product that is transparent over a broad spectral range – from 4 to 18 μm. PIR fibers are capable of operaton over a wide temperature range – from 4K to 420K.

Core / Clad Polycrystalline Infra-Red fibers are used in numerous applications, some of which include spectroscopy and process monitoring, IR radiation delivery to and from the hard-to-reach objects, thermosensing, CO-, CO₂ and QC-laser power delivery systems, IR-imaging.

Key Features

● High transmittance from 4μm up to 18μm

● High flexibility

● Non-hydroscopic and non-toxic

● Low attenuation at 10.6μm (0.2 – 0.4 dB/m)

● Core/Clad design to minimize aging effect

● Suitable for CO-, CO2- QC – laser power flexible delivery

Applications

● Spectroscopy and process monitoring in gases and liquids

● Pyrometry

● Flexible Radiometry

● Flexible IR-imaging Systems

● Power delivery for CO, CO2 and QC – Lasers

Specifications

Polycrystalline Fiber Specification

| Standard Fibers | PIR-240/300 | PIR-400/500 | PIR-630/700 | PIR-900/1000 |

| Core diameter, µm | 240 | 400 | 630 | 900 |

| Cladding diameter, µm | 300 | 500 | 700 | 1000 |

| Minimum bend radius | 50 | 70 | 100 | 130 |

Common Parameters

| Transmission Range | 3 – 18μm |

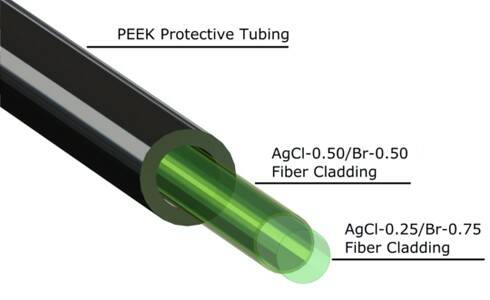

| Core material | AgCl0.25Br0.75 |

| Cladding material | AgCl0.50Br0.50 |

| Protective tubing | PEEK |

| Core Refractive Index | 2.15 |

| Effective NA | 0.28 ± 0.03 |

| Operating temperature, °C | -270 < T < 140 |

| Maximum transmitted Power, W | 40 (CW) |